Plywood is a wood product manufactured out of many sheets of veneer, or plies, pressed together and glued, with their grains going in opposite directions. It tends to be extremely strong, though not very attractive, and is treated in many different ways depending upon its intended application. Because of the way in which plywood is constructed, it also resists cracking, bending, warping, and shrinkage, depending upon its thickness. It is also referred to as an engineered wood, although it is made from a composite of wooden materials, and various forms of it have been made for thousands of years.

The plies that form plywood are generally cut on a rotary lathe, which cuts a continuous roll of wood while a log, called a peeler, is turned against it. Rotary lathing is rapid and makes efficient use of the wood while turning out veneers highly suitable for plywood. Some lathes are designed to expose more interesting parts of the wood grain, although they may be more wasteful of the wood.

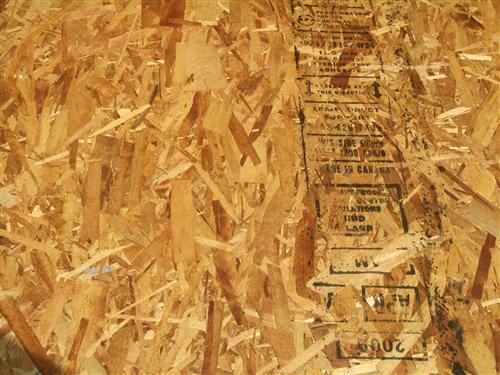

Rotary lathed veneers tend to be dull in appearance, although perfectly functional. After the veneers are cut, they are overlaid with layers of glue and pressed together until dry to form a flat, even, tight piece of plywood. Plywood is sturdier than regular sheets or panels of wood, because the veneers are laid with their grains opposing, which also causes the wood product to resist warping because the grains pull each other tight.

Plywood comes in a number of forms, including softwood, which is made from pine, fir, or spruce. Softwood plywood is usually pale in color and is used in construction applications. It can also be decorative, with a facing veneer of exotic hardwoods. Mahogany or birch are used to create an extremely strong type known as aircraft plywood, because it was utilized in the construction of aircraft through the Second World War.

If plywood is destined for indoor use, it is made with urea-formaldehyde glue, which dries quickly and is inexpensive. For that intended for use in outdoor applications or wet environments, a more expensive water resistant glue is used to prevent the plies from coming apart, or delaminating, and compromising the strength of the plywood. Plies range in thickness depending on the panels they are used in, from 1/10 inch (approximately 1/5 centimeter) to 1/6 inch (almost 1/5 centimeters). Standard sizes consist of 4 foot by 8 foot (1.2 by 2.4 meter) sheets in three, five, or seven plies. The end user can cut, reshape, or sand these sheets to needed specifications.